How Electroplating Enhances Electronics Manufacturing: Explore Its Process, Benefits & Trends

- Regulus Marketing

- Sep 16, 2025

- 3 min read

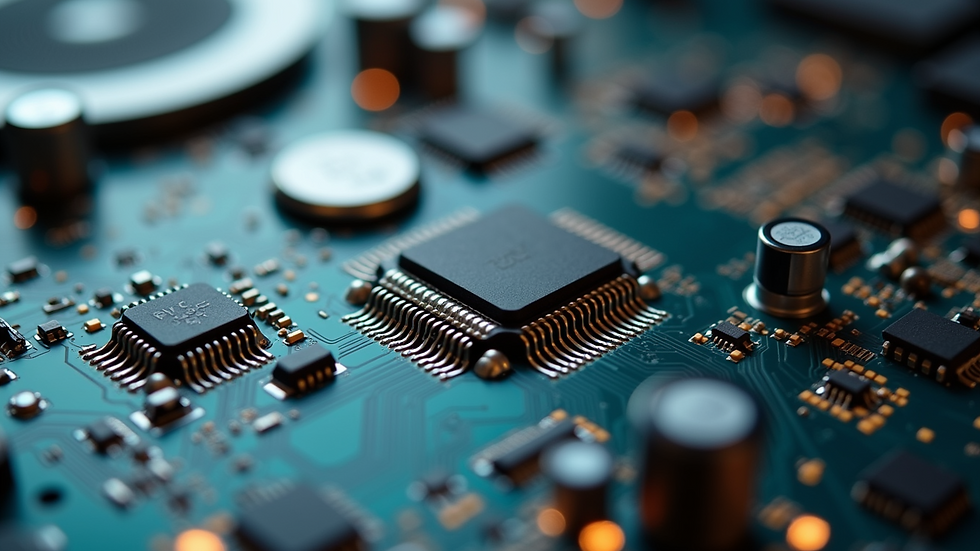

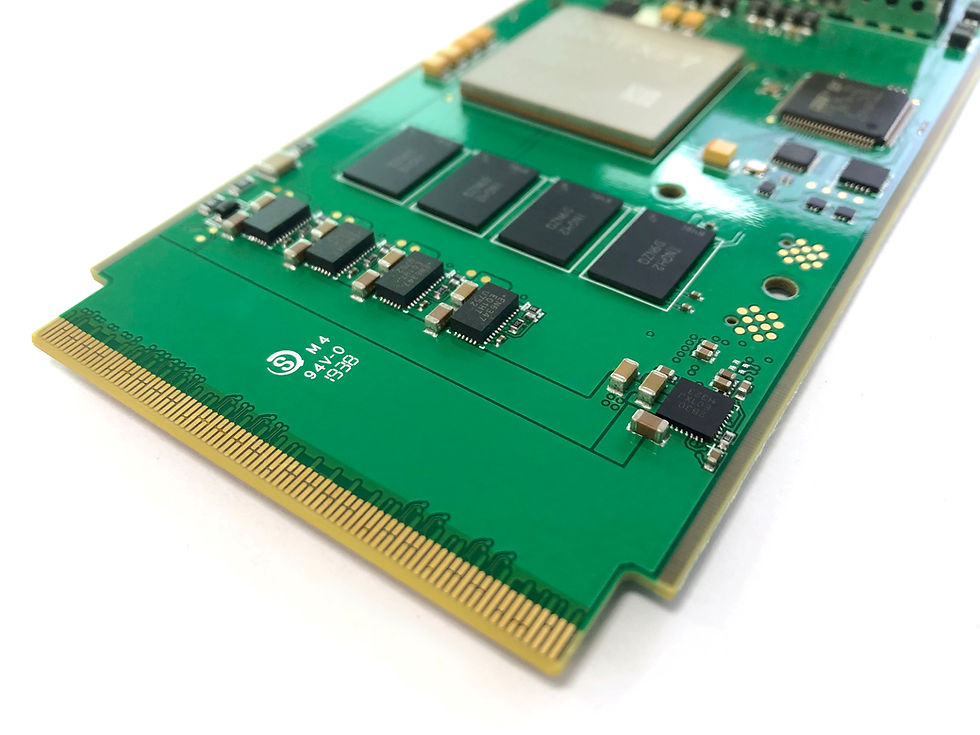

Electroplating is a crucial technique in electronics manufacturing, widely used to enhance performance, durability, and appearance of components. It is a method used to deposit a layer of metal onto a substrate, and it plays a crucial role in enhancing the performance, durability, and aesthetics of electronic components. In this comprehensive guide, we will dive deep into the various aspects of electroplating, focusing on its applications, benefits, and how it is transforming the electronics industry.

Electroplating for Electronics

In the electronics sector, electroplating is primarily used to coat parts with metals such as gold, silver, nickel, and copper. This process improves corrosion resistance, conductivity, and solderability of electronic components. For instance, copper wiring can be plated with a thin layer of gold to ensure better connectivity and prevent oxidation.

According to a report from the International Development Research Centre (IDRC), the demand for electroplated electronic components is expected to grow by 5% annually. This growth is driven by the expansion of consumer electronics, telecommunications, and automotive industries. As a result, manufacturers are increasingly adopting electroplating methods to enhance the functionality and reliability of their products.

Benefits of Electroplating in Electronics

The advantages of electroplating are numerous, making it a go-to technique in electronics manufacturing. Here are a few noteworthy benefits:

Improved Conductivity: Metal coatings increase electrical conductivity. For example, a layer of silver or gold enhances the conductivity of connectors and circuit boards, improving overall performance.

Enhanced Corrosion Resistance: Electroplated metals can significantly reduce the effects of corrosion. This is essential for circuit boards that may be exposed to moisture or harsh environments.

Cost-Effectiveness: Electroplating is an economical way to enhance the properties of base materials. Instead of manufacturing components from expensive metals, a less costly substrate can be coated to achieve desired characteristics.

Aesthetic Appeal: Electroplating also provides an aesthetic finish that is visually appealing. This is particularly important for consumer electronics, where look and feel can influence purchasing decisions.

How Electroplating Works

Electroplating involves a series of steps that ensure the effective coating of a substrate. Here's a simplified overview of the process:

Preparation: The substrate must be cleaned and prepared to ensure the metal adheres properly. This may involve chemical cleaning or abrasive techniques.

Electrolytic Cell Setup: The substrate is placed in an electrolytic cell containing a solution of metal salts. This cell comprises a cathode (the substrate) and an anode (the metal source).

Current Application: When electric current flows through the solution, metal ions in the electrolyte are reduced and deposit onto the substrate, forming a metallic layer.

Post-treatment: After plating, the component may undergo various treatments such as rinsing, drying, and inspection to ensure quality.

Challenges in Electroplating

Despite its benefits, electroplating is not without challenges. Manufacturers face several hurdles that need to be addressed:

Environmental Regulations: The use of chemicals and potential waste generated during the process must comply with environmental regulations, which can complicate operations.

Process Consistency: Achieving uniform thickness of the plating layer can be difficult. Variations can lead to poor performance and shorten the lifespan of components.

Surface Preparation: Inadequate surface preparation can lead to poor adhesion of the plated layer. Manufacturers must invest time and resources into the cleaning process to ensure optimal results.

Technological Advancements: As technology advances, the demand for electroplated components to meet new standards increases. The industry must continually adapt to these changes.

Future of Electroplating in Electronics Manufacturing

The future of electroplating in electronics manufacturing appears promising. With advancements in technology and growing demand across multiple industries, the electroplating process is evolving. Here are some trends to keep an eye on:

Innovative Coating Techniques: New methods such as nano-coating are gaining popularity. These techniques allow for thinner, more efficient layers that provide superior properties.

Green Electroplating: With increasing awareness around environmental issues, manufacturers are exploring eco-friendly electroplating solutions that minimize waste and lower energy consumption.

Automation: Industry 4.0 is prompting manufacturers to adopt automation in electroplating processes, enhancing precision and efficiency.

Research and Development: Ongoing research is essential to improve electroplating methods. Innovations are likely to emerge, enhancing quality and expanding applications.

In conclusion, electroplating is a vital process in electronics manufacturing, offering key benefits such as improved conductivity, corrosion resistance, and enhanced aesthetics. While challenges like environmental compliance and process consistency exist, ongoing innovations and technological advancements continue to drive progress. As demand grows across industries, manufacturers seeking to improve product quality and reliability should view electroplating as a strategic tool for enhancing performance and competitiveness.

Ready to elevate your electronics manufacturing with expert electroplating solutions?

REGULUS provides professional electroplating solutions and a wide range of other surface treatment options.

Contact REGULUS to discover how our advanced capabilities can boost your product’s performance and reliability — with custom solutions tailored to your design and quality needs.

Comments